The information presented is there to be used and enjoyed but please be sure to

acknowledge the source and author if you use any material.

Thorne Local History Society

Keel-a-hoy - Herbert Rhodes

Thorne and district Local History Association

Occasional paper No15: 1993

"The sound of someone hailing 'Keel – a – hoy. Are you there, Captain? Come ahead with that keel' faded away about 1940.

It had been a familiar sound for longer than any living soul could remember. All around the docks of the River Humber seaport, the havens, creek and riverside quays, the warehouse, wharves and jetties – Oh yes, far inland, wherever there was a navigable channel or canal, one could find a wooden carvel – built, square – rigged keel.

My earliest recollections begin in the early 1900s. In the late 1920s, the keels began to disappear gradually as the new steel motor barges, powered by diesel engines, took their place.

The once familiar sound of 'keel – a – hoy' has, like the dodo, taken its place in history. That is the reason I would like to name this book 'Keel – a – hoy'."

So wrote Herbert Rhodes in the mid 1950s. Under the heading 'Lament for the Keel', his memories were printed in three successive issues of the magazine 'Sea Breezes' in 1957.

In this Occasional Paper, these articles are brought together under Captain Rhodes' chosen title.

We thank the publisher of Sea Breezes for their help.

Lament for the Keel (1)

An account of the life and passing of the wooden carvel – built Humber keel, and the recollections of a man who sailed in and commanded several of these craft.

by Herbert Rhodes

The keels I skippered were built of wood, with iron keelsons. Timbers, hooks, beams, and outside hulls were of oak, the flat bottoms mainly of elm, and decks of pine. The craft carried one mast and two square sails from which she took her name, also a pair of leeboards. Her top work was arched – shape so that she might creep under the low arched bridges on her travels up the canals after her gear had been unshipped and put ashore part of the way up the ‘navigations’ or waterways. The length of my craft was usually about 61ft. 6in. 15ft. 2in.-4in. beam, and about 7 to 8ft high to gunwale; their deadweight capacity was between 120 to 130 tons.

In the early 1900s the Sheffield and South Yorkshire Canal was alive with these small craft, loaded with all kinds of merchandise and minerals, hailing from Thorne, Stainforth, Hull, Goole, Beverley – in fact, lots of small villages on the banks of the Ouse, Hull and Trent, and navigations connecting them. It was a fine sight to see these craft in June, around Thorne Fair time, when standing on the canal bank. At Thorne, the keels lay moored there with their burgees, and bunting flying. Men were painting and fettling them, and getting things ship-shape.

Little did the onlooker realise what a complicated trade it was to put a lad to learn. For instance, most lads know what a hammer or an axe is, but when he went as mate of a keel to learn the trade, he found himself in a strange world.

Names of the gear which he had to help work, and the nautical phrases were strange to him and of course there was one taskmaster -the skipper – who had the boy as his sole scholar. The lad looked around to see if there was anyone else to blame if things went wrong, but, alas, there was only himself.

The skipper took him into the small cabin and showed him around, informing him that he had to learn to cook a good meal as well as keep his vessel clean and tidy. In the small cabin he found there were lockers, cupboards, drawers as well as a bunk-each containing different articles such as cooking utensils (frying pan and beef kettles), sewing twine, sail needles and palm, fog bell and horn, ship’s papers and correspondence, small marlin spike, coal, and food, bedding and clothes, all below a swinging lamp. Each was stowed in its different place so that you did not get your food mixed with the coal.

Under the cabin dennings (or floor) was a large brass tap attached to the ship's bottom to let in water for ballast when your vessel was too high to creep under the small bridges. Everything was built snug so that when a man stood in the centre of the cabin all these articles were within arm's length. There was also a small coal-burning stove. This skipper's cabin was built at the after end of the ship while the forecastle was the mate's abode. It contained an oven and stove, a bunk, and in different compartments was stowed the ship's gear, such as the topsail and sheets, the middle brace, spare hatch covers, four navigation lamps, riding ball, two sets of pump gear, hand spike, marlin spike, fid, tar, calico, oakum, mallet and caulking irons, pitch kettle, mop and ladle, davit and blocks, second anchor shackle, forelock and cotter pin, chain flitter1, pair of rowlocks, dog leg2, cathead, small kedge, handlings3, paint, oil, and two anchor chains – each about 30 fathoms in length. By the way, the keel carried two large anchors.

Down a sturdily-built wooden ladder, sometimes used for rigging a stage to discharge cargoes in the hold, you saw the steel keelson (the backbone of the ship), the ludget which received the mast, four large wooden beams, backing boards, shovels, etc. The mast, which was made to lower with a pair of blocks, and through which was run a wire rope leading to the fore roller was made out of a ricker4. A large sheave and two smaller ones were fitted in the mast to work the mainsail, and one near the mast head for the topsail. A weather vane capped the masthead.

The mainsail was made of heavy cotton or flax canvas and sewn by hand. It was square at the head with gores run in from the foot to form its shape and clews. It had a head rope stitched in at the top, a larger leech rope at the sides, and a larger footrope at the bottom, all of which formed the bolt rope. It also had six main thimbles stitched in named two-head thimbles, two bowline thimbles and two larger thimbles for the main clews. There were also thimbles worked in to lace the canvas to the yards and two small thimbles at the foot for the truss line, used for shortening the sail.

Permanent ropes which were spliced to the sail were the earrings for hauling the head sail out on the yard, the gaskets or gaskins to furl the sail when it was made up, the bowline spliced on the leeches of the sail, and a small bridle spliced on the footrope. There were smaller thimbles worked in the leech ropes to take the earrings for hauling reefs out to shorten sail, and two sets of permanent reef points for fastening round the yards. The mainsail was then attached to the main yard, also shaped out of a ricker.

This had two holes through it-both shaped like a slit at each end with sheaves inserted. Permanently attached to the yard were two ropes at the yard arm, named brace ends, and the parrels. The parrels were made of strong hemp rope threaded with bobbins to roll up and down when the sail was hoisted or lowered. An iron clamp ran round the centre of the yard to which an iron link was fixed, and a pair of small wooden blocks to receive the topsail sheet.

Main rigging of the mast was as follows: riggings were spliced in a loop at the top and slotted over the masthead and down to their positions just above the main sheave. The backstay was made of wire rope and in its lower end there was spliced a wooden deadeye with three holes through it, and also a hemp lanyard spliced to the deadeye. Another deadeye was shackled to the after head ledge through which was rove the above lanyard to be made fast and adjusted in its proper place. Next came the shrouds, or side rigging. They were constructed similarly to the backstay but of heavier material. There were four in number, two for each side, and the low deadeyes were hooked onto chain plates on the gunwale, to be adjusted with the lanyard. Next came the main forestay of even heavier material which ran to the fore end of the ship, and which was shackled to a heavy pair of blocks.

The keel also carried a pair of wooden leeboards which were used for the same purpose as the centre board in a small yacht, to stop the leeway of the vessel when she is unloaded and under sail. The leeboard was fastened by the head near the main beam; it was shackled with a heavy chain to the traveller on the coamings, the other end made fast through the fore end of the leeboard with a toggle. Near the after beam was a wooden timber head, named the leeboard stanchion, which was built through the gunwale. Fixed to this stanchion was a sheaved clamp through which passed a chain or wire, the tail chain, one end being fastened to the leeboard tail. The leeboard was worked with an upright roller with one end in the

fowling piece and the other gudgeon end through the rail. A wire fall was rove through a small block, one end shackled to the fore stanchion of the rail and the other to the roller. The block was then run out and shackled to the tail chain of the leeboards. Two wooden winch posts were fitted to the after head ledge to support the mainsail and topsail rollers, these rollers being made of wood. A large wooden cleat was attached to each winch post, used for making the main brace fast, and a smaller cleat for the truss halyards.

The sheet rollers were fastened to the after end of the coamings, and used for working the main sheets. They were composed of two iron stanchions curved inboard at the top. Between them was fixed a wooden roller with a gear wheel at the fore end, and a ratchet at the after end. There was also an iron rod with gear wheels attached. A pawl was fixed to the after end of the pinion rod which fastened together the tops of the stanchions. When shipshape the gear weels, married, gave you double purchase power.

Wire mainsail sheets were run from the roller across the hatches, through a fairleader sheave, which was fixed to the coaming, then through a block fixed to the gunwale, and finally shackled to the clew of the mainsail. The tack rollers were built in an iron frame, one end of which was fixed to the forecastle deck and the other to the head ledge. The roller ends faced bow and stern; the tack chain was run off the roller, through a bush in the tack timber, and shackled on to the clew of the mainsail.

Height of the mainsails that I worked was about nine yards from the centre of the foot rope to the centre of the head rope of the sail. The width of the head of the sail was about 19 breadths of canvas. The topsail was a square sail of very light, strong canvas; it had two carring thimbles at the head and small eyelets for the lace line, also two thimbles in the clews. Permanently attached to it were hemp rope earrings and a lighter manila rope for lace lines. It was only used in a light wind or when the wind was favourable and when in use was made fast to the topsail yard.

The method was to make one earring fast to one yard arm and then haul the other tight out to the yard arm and make fast. This sail was then laced on the yard starting from the centre and working outwards. Made from a ricker, the topsail yard was much lighter than the main yard with an iron clamp fastened round the centre and an iron link attached. There were two holes bored through at each end to receive the earrings. When not in use the topsail was made up snug and stowed away in the forecastle. A block was fixed to the mainsail tie and another to the after head ledge, halyards were rove through the blocks and the running end attached to the topsail roller. This gear, when rigged in its proper place, was the keel rig.

Anchors were worked by a windlass fitted into stout bitt heads at the foremost part of the forecastle deck and the keel steered by a wooden tiller slotted into the rudder head when in use.

A small boat was very often attached to the stern by a painter when the keel was operating in rivers and similar narrow waterways and was sculled by an oar which fitted in a notch on the boat's transom. With the wind fair and your sails set, the yards were square with the ship, and were controlled by the braces and the sheets hove into position. When you hauled the wind to port the port tack was hove down in the bush, your sail hauled in position and the sheet adjusted and bowline hauled. When hauling the wind to starboard the same work was done, reversing port for starboard.

In tidal rivers, where it was wide enough to work or beat against the wind, you relied on the current of the tide for help. I will try and explain the art of tacking or 'staying' as our fellows termed it. If you were nearing a lee shore and your sails were tight hauled on your port tack, to come about and put her on the starboard tack required the following work. The skipper would put his helm to starboard until the fore end of the sail came off back; he would then lift the sheet pawl and let-go his port leeboard. The mate would release the tack and heave the slack of the starboard tack tight (the lee brace was held firm and the bowline fast, the bowline making the fore end of the sail do the work of a foresail, as in a yacht).

The skipper, watching the weather vane until the keel's head had pulled far enough, would order the mate to release the bowline and heave the starboard tack down. The skipper hauled on his starboard brace and then hove the sheet in, the helm being put to port. When the sails were trimmed and the bowline hauled, the keel was again back on her course, running up to windward on her starboard tack. When nearing the weather shore the skipper would port his helm and the same work applied, only the term port substituted for starboard

***********

The earnings of a keel for cargo were known as a freight. When I agreed with the owner to take charge of a keel, my agreement generally ran as follows: 'The owner to pay for the maintenance of the keel and gear, insurances and such.’ His reward was one third of the keel’s earnings; my duty was to find the cargoes and freights. All the expenses such as the mate's wages, haulage costs, loading and discharging costs etc., were paid by the skipper, who also victualled the keel. The skipper’s reward was the remaining two thirds of the freight. Freights were drawn by the skipper who paid the owner his share.

My grandfather, a keel man all his working life, died at the age of 82 about 1905 and my father, a skipper and owner, died in 1939 aged 76. They often loaded coal from collieries, such as Kilnhurst, Denaby, Manvers Main, sometimes receiving a bonus from the colliery companies for keeping the pits working when short of railway wagons. The colliery agent informing them of the price of coal at the pithead, they would proceed with the cargo to Hull, paying navigation dues and all expenses on their voyage. They would then sell the coal for the best price they could make to trawler owners, shipping firms, or various mills. When the cargo had been discharged they paid the agreed amount to the skipper who would then pay the colliery agent for the coal; the money left over was the keel’s freight.

I once left my keel, the Britannia, at Beverley and came home to Thorne for the week-end. Here, at home, I received information that a well-known local councillor and farmer named John Mitchell wanted to engage a keel. I went to his house. Old John said to me that he had 10 tons of nitrate of soda in Victoria Dock at Hull, and about 50 tons of tillage at Keadby tillage works. I then had to call at Garthorpe Shore, and finish loading up with his spring corn, ploughs and harrows, and other farm implements. When I was loaded up he wanted it taking to Rusham Farm, near Drax. I had to deliver the farm gear and three parts of the tillage there, the remaining tillage he wanted taking to New Bridge, up the Aire and Calder.

I replied that I would complete the work if we could agree about the freight. Old John replied in broad Yorkshire: 'Atter going ter ev it by lump, or tack, or oor?' Eventually we agreed on the price, our agreement was written out, a stamp affixed, across which old John and I signed our names. I completed the work to the satisfaction of both.

The Port of Hull was the chief centre for the trade of the keel. Other chief industrial towns they traded to were as follows. Place an imaginary left hand pointing up the River Humber at Hull; the thumb points up the river Hull to Beverley and Driffield, the first finger up the River Ouse to Selby and York, the second finger the Aire and Calder Navigation to Leeds and Wakefield from Goole, the third finger the River Trent to Keadby and the Sheffield and South Yorkshire Navigation to Doncaster and Sheffield, the fourth finger the River Trent to Newark, and to Lincoln up the Foss Dyke Navigation from Torksey. We also traded to the ports of Immingham and Grimsby, on the Lincolnshire side of the Humber, below Hull.

Main trade for keels was merchandise and raw materials from Hull to the industrial towns and cities. The return cargoes included coal, pitch, slag, steel and other finished products. Sometimes we loaded a cargo of Trent sand and gravel dredged from the bed of the river by hand; the skipper would pay all expenses and when loaded the cargo belonged to him. He would then sell it to the best market, his customers being corporations, builders’ merchants and contractors.

A skipper had to know the times of changing of the tide (high water and flood tide) in different parts of the rivers which he arrived at by reckoning from the time of high water at Hull, forecast in a small tide table which he usually carried. He also had to know the different drafts of the rivers or ‘navigations’ in which he had to travel; also the weights his keel would carry at different drafts, to enable him to agree for cargoes which he had to carry up various navigations. The keel carried no maps or charts. He had to know the safe roadsteads in the rivers to ride at anchor, such as Hull Roads, Walter Dykes, Blacktoft Roads, Burr Wheel and Cliff End among others.

Keels were built at various small shipyards on the banks of the rivers and canals. For example, the five different keels I had charge of were: The Unity, built by Stanilands of Thorne; the William & Jane, built at Goole (both these owned by my father), the Britannia at Dunstons of Thorne; the Daybreak at Goole, and the Daystar at Mexborough.

Nearly all keels wore a burgee at the masthead on festive occasions. It was a large flag, made of bunting, with the Union Flag at the hoist. The burgee, which carried the name of the keel in large letters worked in it, ranged from 14ft. to 16ft. in length, and 5 to 6 ft. at the widest part.

The keels owned by the Wilson Line of Hull flew a small pennant at their masthead as a weather vane. This large shipping firm had a fleet of keels to carry cargoes to Sheffield, and coal back to Hull from Manvers Main to refuel the large steamers.

All keels had to have a port of registration, some were registered under the Board of Trade and others under the Canal Act.

It will of course be readily realised that the passing of the Humber Keel is closely connected with the passing of her big sister, the 4-masted barque. In 1939 I was skipper of the keel Datstar, owned by Hanley and Company of Doncaster. I loaded a cargo of Australian wheat out of the stately old barque, Archibald Russell, then lying in Alexandra Dock at Hull, discharging her cargo. I took my cargo and discharged it at the Flour Mills, Doncaster. The war years passed on and the barque, after being dismantled, was towed up to Goole and used as a warehouse. In 1945 I was skipper of a barge named Golfer, owned by G. D. Holmes of Goole, when I loaded a cargo of Ouse sand. I discharge the cargo into the Archibald Russell (lying in the West Dock at Goole) as ballast, for she was being prepared for her last passage down the River Ouse and Humber. It seemed to me very much like going to the funeral of an old comrade.

I myself can hardly realise that the old crafts and wooden keel building, mast and block making, sail making, rigging out of keels and the manning of them, have vanished, never to return. The wooden-built Humber keel has now been replaced by modern steel barges, propelled by the latest oil engines. I must pay tribute to the old engineers, long since passed on, who made my trade possible by the bridges they built, as well as the locks and weirs to dam the water. To raise a keel dozens of feet over hill and vale is surely a work of art, and great credit must be given to these men of a bygone age.

Many and varied were the hobbies and pastimes of my comrades in the keel trades. Some played for rugger clubs, others were soccer fans, while a few fished in the waters around them. Some carved models or went in for joinery, others painted and carried out graining, signwriting and gilding. Many made fancy knots such as Turk's heads, and sennit for fenders and rudder heads; some made mats of old bass rope, rugs and suchlike, while a few played musical instruments such as melodeons, fiddles, concertinas or mandolins, all of a handy size for stowing away when not in use. My chief hobby was reading-frequently about Capt. Cook or explorers like Amundsen and Nansen. Occasionally I amused myself and the mate by playing the mandolin when we were brought up at anchor, or moored in lonely places up the navigations; of course, in those days there was no radio.

Hull keel regattas were held in the 1890s when the keels were lined up, riding at anchor, opposite Hull Pier on the River Humber. A starting signal was given and the crews would then weigh anchor and set their sails to race round Burcome buoy, near Grimsby. The finishing line was off the pier. Keels were manned by the skipper and four other men for this kind of sport, skippers showing their skill in navigating their craft and harnessing the wind and tide as a farmer might harness his horses to the plough. This sport ceased in the early 1900s.

Keelmen’s aquatic sports have been held on the canal at Thorne since the 1890s, always in June, except during the wars. Sports include swimming, greasy pole walking, sculling races, propelling a boat by hand with a crew of two or four men in the boat, and other interesting events. It was impossible to learn the keelman's trade at a Nautical school. Only the hard, rough school of experience, and the knowledge and skill of the old skippers could produce a trained keelman.

I shall have more to say, by and by.

The Mastmakers

by Herbert Rhodes

When I was a lad I used to play in Dunston's yard at Thorne, near Doncaster, where old Ned Rippon, in the mast and blockmaker's shop, used to think nothing of trimming a ricker pole, almost 60ft. long. In the long shed, with a large draw-knife in his hands, he would work in shavings up to his knees.

The ricker poles were laid on trestles down the length of the shed and secured with wedges. Outside was a large rack in which the masts were reared upright so that they could season. This was a sturdy shed whose rafters were used for heavy lifts as well as storage. Ned and his men turned out a surprising variety of products: Barge poles, sounding rods, masts for keel and sloops, booms, gaffs, large deadeyes for shrouds and small for backstays and manropes. And there was quite a business in catheads, fidds, tillers, windlass barrel ends, mast trucks, handspikes and mop handles.

Other products were large fancy bungs for the fresh water casks which all classes of craft carried at that time, and the wooden parts of pump gear-handles, low box and bucket. Main and topsail, sheet, tack and leeboard rollers were also fashioned here besides blocks, sheaves and parrels.

Tools of ancient name and origin were common in the shed. Adzes, mattocks and a variety of shaped iron tools used for putting smart grooves in deadeyes so that lanyards could be rove.

A boy who wished to become a journeyman mast-and blockmaker was required to serve an apprenticeship of seven years.

Lament for the Keel (2)

The second of three articles describing life on board the sail-carrying keels in the rural and industrial hinterlands of Hull and Goole and other Humber ports.

By Herbert Rhodes

The first of the motor-driven barges which eventually ousted the keels arrived in the early 1900s. She was an iron built barge named Good Luck, afterwards the Swiftsure, propelled by an engine using paraffin oil for fuel. The first two skippers to take charge of her were named Richard Brock of Hull, and Sammy Fowler of Stainforth.

In passing I may say that I am writing this article as I lie ill in bed, having no notes or papers to refer to, only memories and recollections to draw upon.

When I left school in 1907 at the age of 12, I was very fortunate for I could read and write; most of the keel lads could not. A good many families were reared on board, and some of my friends had only a week or two of schooling at a time; others none at all. Some of the agents a keelman dealt with were also poor hands with a pen. I once remember an agent at Hull sending by post an order to load a cargo of coal to a skipper. The address ran as follows: c/o Dalton Main Colliery Office, Nr. Rotherham. The letter was lost for about a month, but eventually arrived. It had been to Rotterdam in Holland, causing much inconvenience to the people concerned.

Many were the names and phrases a mate had to learn, each with a definite meaning. His parents taught him there were two sides to a question, the skipper that there were inside and offside, nearside and farside, starboard side and port side, foreside and afterside, weather side and leeside, topside and lowside, broadside and alongside, deckside and coaming side, over the side besides right side, and, if you happened to get on the wrong side, you could keep a good look out for your backside.

There were fenders made of rope, cork fenders, grommets, different knots, such as goosenecks, reef knots, sheepshanks and various names for hitches, such as half-hitch, Black-wall hitch, etc. he had to learn how to rig a derrick for discharging cargo, to make and use a Spanish windlass and the like. He heard such phrases as-slack a bit of sheet and haul your weather brace; heave your tack down and haul your bowline; ease your lee brace and let her keep up, don’t let her come up in the wind with you; put it athwart and not fore and aft; keep her steady, etc. If you had been riding at anchor in the river and were getting ready for under way, he might have heard the following; All right, heave your chain in while I break her sheer. Take a weather bit, the chain's slipping; put your flitter in and flit over while I keep her steady. Heave in now; she has tripped her anchor; take your riding ball down-or anchor light (if it were dark).

Each keel, of course, had a name and what a collection they were. When I first went on board they ranged from Adam to Togo, the victorious

Japanese Admiral, and there were also affectionate names such as Mary Ann, Two Sisters, and so on.

Wilson’s Line of Hull had a fleet of keels, the initial letters of their names ran through the alphabet. They were the Ant, Bee, Comet, Dove, Eagle, Flake, Glade, Harry, John, Jane, Kate, Lily, Minnie, Nero, Ouse, Prince, Quill, Rose, Swan, Thomas, Una, Vine, Wasp, Xerxes, York, Zulu.

Some of the names of the 4-masted barques I loaded Australian wheat out of were: Parma, Passat, Pamir, Olivebank, Priwall and others, while the units of the United Towing Company of Hull which operated up the River Trent had names ending with the suffix ‘man’ Norman, Bowman, Yeoman, Motorman, etc. The only water for drinking and household use was carried in buckets drawn from the canal where keels navigated. In fact, practically the whole town of Thorne where I was brought up, within 100 yards of the canal lock-depended on the canal for water. From our house it was possible to watch the skippers trimming their sails as they penned through the lock and the entrance to Staniland's shipyard was within 50yds., of our front door. It had two building berths, two dry docks and a large timber yard for seasoning the timber. About 200yds. below the lock was Dunston's shipyard where there were building berths, one dry dock and a slipway. We had permission to go up to Dunston's old ropery to school, where we used to see Mr. Butler and his workmates spinning hemp into ropes. They walked backwards with a coil of hemp round their waists, tousling it away, while at the other end of the walk a youth was turning the spinning wheel by hand.

We spent many an hour in these shipyards, watching the carpenters repairing old wooden keels and building new ones; timbers, beams and plankings were all saw by hand over the sawpits and shaped to measurements with adzes and planes. I recall the clatter of the carpenters' caulking mallets, the boiling pitch and escaping steam-like a fog-when the men carried long planks out of the steam house, to be bent round the head or stern of the ship they were repairing or building. The planks were hammered home with large spike mauls, all the work being done by hand. Then came the great day we had been waiting for.

'They’re launching today'. 'Where at?' Dunston's or Staniland's, it was usually on a Saturday when we were not at school. Off we would go and receive permission to go on board the new ship on the stocks. A shout from below; 'Are you all ready?' Clash, bang went the hammers knocking the chocks and wedges out. ‘Here she goes, hold fast!’ and away we went, the new vessel dropping broadside on, with a splash that sent the water rolling over the far canal bank. Up went the burgee, with the new ship’s name on it, and in the water all around were wedges, slipways, and the timber used for launching purposes.

When the new ship was berthed my pals and I would climb ashore-quite as proud as Capt. Cook when he discovered Australia. The new ship was then known as a dumb barge. They would berth her alongside Dunston's sail loft for the rigger, Ned Rippon to fit the mast, yards, wooden blocks and deadeyes. Mr. Butler did the wires, rigging, and ropes, Kernal Sanderson was responsible for the sails and hatch covers while Old Jack Lee did the blacksmith's work, and Old Sammy Carr sniffed round to see everything was perfect. There was a final survey by Mr. Dunston and the new owner before being handed over.

When the dumb barge was rigged out she became a keel, but if she was rigged with a pine mast and fore and aft sails-which included a mainsail and foresail-she became a sloop. During my school holidays my father would take me on board his vessel for a trip. He was then trading from Keadby with coal, discharging it into the fishing trawlers in St. Andrew’s Dock, Hull.

At that time there were dozens of keels laid alongside in tiers six or seven abreast, waiting their turn to discharge to the different owners. I recollect my father, on one of these trips, pointing out to me the place where the sloop Masterman capsized and sank with the skipper's wife and two children in the cabin, after striking Witton Sand end on the previous spring tide. The Masterman and her ill-fated passengers were never seen again.

In November 1907, I left school and started my career as a mate. My father, and elder brother and myself joined my father's keel Unity at Medge Hall. She was on a voyage from Hull loaded with a cargo of iron ingots weighing half a ton each, bound for Dunford and Elliot’s Wharf at Attercliffe, Sheffield. The canal was frozen over and when the icebreaker had passed us a Thorne boat hauler, named Johnson, hung his horse on to pull us up the canal to Thorne, my father steering, my brother and myself pushing the floes of ice round the vessel’s head with a small boathook. Eventually we arrived above Thorne lock, after putting the leeboards ashore.

We set off next morning about four and when I turned out of my bunk we were at Bramwith lock. Just above the lock we passed on our starboard hand the New Junction Canal, connecting the Aire and Calder Navigation. Through Sandall lock and on to Doncaster, where we changed horses, then on through Sprotborough locks with narrow walls and an old water-driven mill, by Warmsworth limekilns under a very high railway bridge to Conisbrough lock. On again, under the railway bridge close past Cadeby Colliery to Denaby lock, past old Denaby Colliery to Mexborough where we landed our mast and sail at about 6 p.m.

Next morning we started about 4.30, the horse pulling us up the shallow and narrow canal. It was as dark as a grave, except where lit by the glare of glass-houses and forges built on the canal banks. As we approached the glass-houses of Mexborough and Swinton we could hear the workmen singing like a choir. We glided by and a large red glow suddenly appeared; I could see men with long tubes in their mouths blowing bottles and other glassware-a strange sight for a lad so early on a winter’s morning.

I could hear my father calling to the horse marine to go steady, or stop, as he navigated the narrow bridges and locks, the keel practically scraping the bed of the shallow canal. My brother and I stood by with fenders and helped to work the lock gates and cloughs. We passed through Swinton lock and on our starboard side saw a branch canal with a lock at the entrance. It connected the collieries at Manvers Main, Barnsley, and several others, eventually joining the Aire and Calder Navigation at Wakefield. We passed the chemical works and a large forge at Kilnhurst, to move on through a nearby lock. I recall the rattle of the colliers' clogs, to or from the pit, locally known as 'Bob's Oil.' After passing the coal staithe we went through the cut end lock into the River Don again.

Here, there was a ferry which took our horse and man across the river. Winding our way along we passed the Dalton Main coal staithe on our starboard side and penned up through Aldwarke lock and up the river to Eastwood low lock, where we entered the canal on the starboard side of the river. Our horse and man were again ferried across the river. We passed Aldwarke Main coal staithe on our right and went through Eastwood top lock. About a mile above we passed another small canal named Rotherham Goit, with a small shipyard on its banks, Parkgate Forge and a small colliery higher up. At this period great quantities of slag were loaded here at Parkgate for shipment at Hull and Grimsby.

(TO BE CONCLUDED)

Lament for the Keel (3)

This article concludes the reminiscences of the author, a North-countryman who

has spent his working life in Humber keels, a craft now gone from the rivers and canals of Yorkshire and Lincolnshire.

By Herbert Rhodes

On my very first voyage we went via Rotherham with its electric works, glasshouses, breweries, potteries, to the Canal Company's wharf and warehouse. A large trade was done here at that period; the keels discharged all kinds of merchandise: Flints and white sand for the glassworks, and red moulding sand for the ironworks. Outward cargoes comprised grindstones of all sizes from the hand size up to half-a-ton in weight, new railway wheels and axles, bundles of steel, etc., for shipment from Hull and Grimsby.

Through Rotherham, we left forges and rolling mills to port as we entered the river again, with the main railway station close on our right. Passing more ironworks, we entered the canal again. Nearby the River Rother joins the Don with a fine flour mill on its banks which at that time ground foreign wheat brought by keel from Hull. Through Ickles lock was another large forge and ironworks to the right and near Holmes lock a pottery where later we discharged a cargo of China clay, when I was mate with my eldest brother. On we went through Jordon lock entering the river again. On our left was a large weir and to the right a large sewerage scheme under construction. We entered Tinsley low lock by the large steel works at Templeborough. Leaving the last stretch of navigable river behind we proceeded through a chain of four locks.

Above the second lock were Tinsley rolling mills and forge, dim in their own mist and beyond lay the Canal Company's pumping station with the main purpose of pumping water out of the Don into the canal above the last lock (named the Top Level).

Every boat which passed through the top lock, took a lockful of water out of the top level and the pump was there to replace it, attempting to keep it up to the depth required. After passing through the four locks and up a short canal we entered the low lock of a chain of eight locks. Climbing these locks we passed the Canal Company's wharf where two steam cranes were busy discharging cargoes. On our right were large ironworks rolling great ingots of white hot steel into lengths of wire.

The canal was well above the level of the works where the clashing of the large steam hammers, the steam exhausts, the tell-tale buzzers on their boiler gauges, the rattling of the scrap iron, shunting of railway engines, and the shudders which shook our ship astounded a lad such as I who had been brought up in a rural town.

We left the top lock, came to a coal staithe and through a single line railway bridge could see Tinsley Park Colliery with a canal basin in which

lay a small fleet of low flat iron barges. On their tops were fitted narrow gauged rails, running fore and aft, to receive small coal tubs named 'corves', straight out of the pit. They were pulled by pit ponies driven by youths and the skippers were black with the coal dust and smoke from the large braziers which stood on the iron deck near the tiller. Their destination was a small basin in the heart of the city of Sheffield.

On we went under several bridges to find ourselves atop of the world, on an aqueduct carrying the canal over a main street at Attercliffe. On again and under a low railway bridge and we could see our destination. But there was still a small peninsula running up from the bridge and we had to be at the other side of it. We nosed our way into the entrance and brought the horse line aft, the horse pulling our ship practically round into the small gutway alongside Dunford and Elliot’s wharf. It was about 6 p.m. Next day we discharged with a steam crane. On this, my first voyage, we had climbed through 30 locks, and a considerable height, carrying 90 tons of iron ore which had come from the mines of Sweden.

In the days of my youth between Thorne and Hull it was possible to meet all classes of craft from small rowing boats to the large merchantmen at Hull. Plying between Doncaster and Keadby were two small steam screw tugs named Hebe and Don, skippered by David Oglesby and his son. There were keels, slops and 'billyboys' which traded to Louth and places on the Humber Estuary and even to Boston. The dredger groaned and squealed as it bucketed the mud from the bed of the canal into low oblong flat boats. Out of Keadby lock into the River Trent we often glimpsed Thames barges and sloops, with their large red tanned sails contrasting with the white canvas of the keels. Tugs towed us down the river-some with seven or eight keels in tow, on two ropes one off each quarter.

At Trent Falls we entered the River Humber and met the traffic out of the Ouse. You might see the old Shah, a sea-going paddle-tug owned by the Goole Towing Company, with a couple of large lighters come down from Goole with coal and bound for London. The Goole tugs towed schoolers and 'Dickys' (coasters from Goole) bound for the Continental ports and the ports around our coasts. There were also tugs with dumb barges from the West Riding, from York, and from Selby. Leethams' steel steam keelstowed large lighters loaded with flour; all navigated the river together, clearing the buoys and lightships, which mark the river channel. You would also see two steam keels – the Atalanta, making her way back to Hewitts’ brewery at Grimsby for a refill after discharging at Gainsborough or Doncaster, and the Swift from Brigg, on a voyage back to Hull for another cargo of oil seeds for the Farmers’ Company at Brigg. Riding at anchor near Reads Island you might have seen an old wooden sloop after voyaging from Hull with a cargo of live cattle to graze on the rich grass of the island.

Approaching the Fish Docks you would doubtless see an old paddle steamer moored alongside the jetty, topped up with a deck cargo of fish, bound for New Holland, Ferriby Sluice, Witton Jetty, Burton Stather or Gainsborough. There were two such craft; one named the Magna Charta, the other the Isle of Axholme. In Hull Roads there were all kinds of craft, large and small, riding at anchor. You could see the topmasts and yards of the sailing ships, masts and funnels of the steamers sticking out above the warehouses in Victoria and Alexandra Docks, and small Customs and pilot launches running backwards and forwards to the many ships riding in the Roads.

The ship which appealed to me most was the old man-of-war, H.M.S. Southampton, one of Nelson's wooden walls, which used to anchor in the Roads for nine or 10 months each year. She was used as a prison ship for youths with strict discipline and nautical classes, officered by old naval salts of the wind-propelled Navy. I remember her so well and also my father, who in threatening me with punishment, tried to frighten me by saying: 'I'll put thee where't dogs won't bite thee, I'll put thee aboard owd Southampton, I will that.'

An old saying is ‘best part about going to sea is coming back home again' and how comfortable it all seemed to be when we returned home and moored above Thorne lock to stroll home for fresh food and clean gear, ready for an early start next morning.

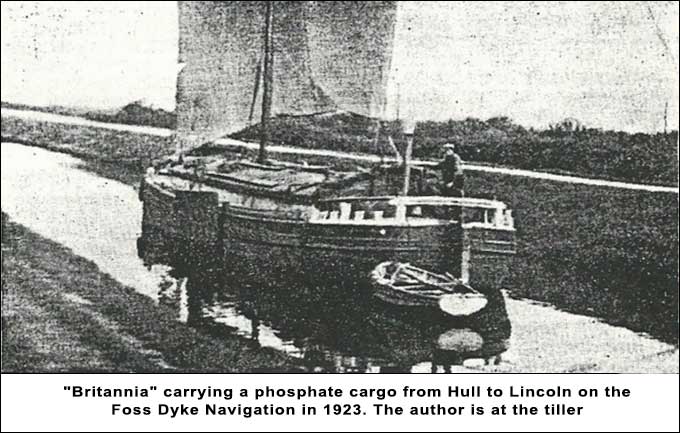

About 1923 I made a voyage from Hull to Lincoln. We started up the Humber, entering the River Trent at Trent Falls, passing Burton Stather hills on our left with agricultural warp land to the right. On we went to Flixboro, where later, in the 1930s, a large wharf was built to receive iron ore and coal for Scunthorpe ironworks. We passed Keadby lock on the right hand (the entrance to the Sheffield and South Yorkshire Navigation) to go under the fine road and railway bridge and left the tillage and oil works on our right.

We passed Bowingham (left), and Althorpe (right), through agricultural land to East and West Butterwick, winding our way past Ouston ferry. These villages then had old windmills to grind the grain grown in the rich soil around them. Turning and weaving our way to West Stockwith, where the River Idle flows into the Trent, there was a lock to take us into a basin marking the entrance to the Worksop and Retford Canal, supplied by the River Idle.

It was here that the keels' cargoes were trans-shipped into the long narrow boats for Retford and Worksop. The narrow boats returned with coal from Shireoaks Pit, as well as bricks and other manufactures.

Proceeding on our journey up the Trent we passed Stockwith Chemical Works with jetties built on the riverside to receive raw materials such as copper ore, phosphates, arsenic etc., and to ship blue billy blocks, and sheep dip for Middlesbrough and Australia. The works were owned by Morriss, Little and Company, but are now demolished. Passing Walkriffe Ferry where the river wound and twisted in tight bends, we came to a very sharp turn indeed at Morton. It may best be explained like this. Suppose you were towing up, dark at night, and you were fourth keel on the tug, you would see the tug’s green light and her mast headlight on your starboard hand, for he would be pulling out of the bight in which your keel was heading.

Next came the market town of Gainsborough, with its shipyard on the right and on the left a large engineering works, flour mills, oil mills, warehouses, granaries, malt

kilns, and coal wharves. Through the stone-built toll bridge are oil and cake mills, the Great Northern Railway Wharf, Newsham’s timber depot, with keels

discharging foreign timber from Hull and Grimsby. And so under a railway bridge which carries tracks running to our destination – the city of Lincoln.

Onwards under Torksey railway bridge we saw the old ruins of the castle and about a mile beyond entered the Foss Dyke Navigation through a lock at Torksey. Here we had to rig a derrick and trans-ship part of our cargo into lighters. The reason for this was that on occasions we loaded to a draft of 7ft., and there was only 5ft. of water in the Foss Dyke. The skipper hired these small craft and was responsible for them until they were discharged and returned to Torksey. The skipper and his mate then had two, perhaps three craft and cargoes to navigate to Lincoln. We tethered the small lighter with cross ropes to the keel’s stern and with the sails set, and the mate steering the lighter, we would crawl-very steady it seemed after being in the tideway-towards our goal.

The next place of note was Saxilby, where we had to lower the sails and mast to pass under a bridge. Leaving the village on our left we crept along passing the tillage works on our right and Odder pumping station to the left. This pumped water out of the drains in the fen district, into the Foss Dyke to be run out of sluices into the River Witham at Lincoln, and eventually into the North Sea at Boston.

After passing a small ferry we wound our way past the Old Pye Wipe public house and on past the racecourse side into a large expanse of shoal water called the Brayford. We had seen Lincoln's ancient cathedral miles away and thought we would never reach it. But here we were at Lincoln with 500 quarters of wheat in the keel and lighter. We rigged a derrick to our mast and moored the lighter between the keel and the wharf. The skipper, his mate, and a casual man engaged by the skipper, would then begin discharging. One man hung the bags on and swung them to the draymen ashore while the other two heaved out, hatches and covers were laid, and the derrick lowered, unshipped and stowed away; thus ended another journey.

The skipper washed and tidied up, and away he would go with his Bill of Lading to the flour mill office to draw his hard-earned freight. At the top end of the Brayford, the navigation turns sharply to port under an old sturdy stone bridge named the Stonebow Highbridge (I don’t know why; I should call it very low). Said to have been built by the Romans, it lies in the centre of town, with shops and property built on it. Further along are a lock and sluices connecting the River Witham.

On another occasion we made a passage from Hull to Newark up the wide Trent to Torksey where we made fast to a small paddle-tug, the Robin Hood. Although her draft was only 2ft., she had great power for pulling against the current higher up the river. We went with the spring tide and with flat grazing land around us, turning and twisting, passing small villages such as Laneham, Dunham and Clifton. These are built some distance from the river banks so as to be on higher ground in flood time.

Under Dunham toll bridge and Clifton railway bridge we passed keels dredging the river bed for the excellent gravel and sand. Here the tide spent itself against the water that flowed through Stoke-on-Trent, Nottingham and Newark on its way down to the North Sea.

We wended our way through the deserted countryside with only the noise of the water as we towed against the stream, and the sound of distant church clocks, the birds, and the cattle grazing on the rich grass for company. Eventually we passed Carlton-on-Trent, a small village, and arrived at Cromwell lock and weir; here the river Trent ceases to be tidal. Above the lock we passed Muskham and other small hamlets, and after winding our way round the turns and bends eventually arrived at Newark low lock. The tug’s journey ended for she was too large for the lock. We were then towed by a pair of horses up the river to Castle lock, passing on our way large fertiliser works, mills and malt kilns, and so under the Great North Bridge, Newark’s fine old castle and the beautiful old church with its long spire are worth coming a long way to see. Through the lock and into a basin we went to arrive at our destination.

In 1923 I made a trip to Leeds in the keel Britannia. We loaded 500 qtrs. Of wheat in Alexandra Dock, Hull for the C.W.S. flour mills at Leeds. After towing up the River Humber we entered the River Ouse, near Blacktoft. Winding our way past Whitgift, with its small lighthouse, and several small hamlets, including Saltmarshe and Swinefleet, we entered the lock at Goole and so into the Aire and Calder Navigation; here we were towed by a screw tug having about seven barges, in all in tow. On our left we passed the New Junction Canal and moved amid agricultural surroundings to Pollington lock, large enough to hold our tug and barges. We then proceeded through Whitley Bridge lock. Approching Knottingly, on our right lay a chemical works and the entrance to the Selby Canal (connecting this navigation with the River Ouse at Selby) and on our left a shipyard, glasshouses, and further on-potteries. Soon we were in a cut end lock to enter the River Aire at Ferrybridge. Slipping past the electric light works on the left and Brotherton village, opposite, the keel moved up the 5-mile stretch of river to Bullholme lock at Castleford-a colliery district with glass, pottery, and milling industries. The keel went through the cut end lock into the river again where the River Calder joins the River Aire.

Past Ollerton Main staithe on our right, we entered Kippax lock into the canal where the locks hold three barges at a time. Through Fish Pond and Lemonroyd locks we left behind the village of Allerton Bywater, and the Saville and Water Haigh Collieries, from which a large amount of coal is still carried by water. Thus onwards past the B.Y.B. brewery at Woodlesford and the large chemical works at Rothwell Haigh to Nostrop lock. We entered the River Aire at Nostrop cut end, Hunslet, and so to Leeds lock. The keel then moved under Lees Bridge, near the market, and soon lay alongside the Co-op flour mills which are in the heart of this great industrial city.

Thus far I have described the craft and the routes between town and city used by the keels and sloops. In rural areas it was generally a case of rigging our own derrick to discharge cargo. In the fine old minster town of Beverly my mate and myself would begin to put the coal cargo into baskets ourselves after rigging the derrick and gantry while two men 'heaved out'. There was usually a fifth man on shore with a wheelbarrow to transport the baskets into the coalyard.

As soon as we had discharged, the hold was swept out, the derrick lowered and gear stowed away. From the mouth of the River Hull at Hull, or Kingston-upon-Hull to give the city its rightful name, the keel was navigated by stowers as well as by the sail when suitable. A stower is a ricker pole about 22ft. in length with a pommel at one end for the shoulder and a grapnel on the other.

In these three articles I have endeavoured to present a picture of life in keels as it was two or three decades ago. In the keel the landsman was afforded an unusual opportunity to see a craft under sail constituting an ancient link between sail estuary and meadow.

Published by Thorne Local History Society

Supported by Thorne Moorends Regeneration Partnership 2014

© Thorne Moorends Regeneration Partnership. All Rights Reserved.